Energy Recovery Project

Sunset Arena

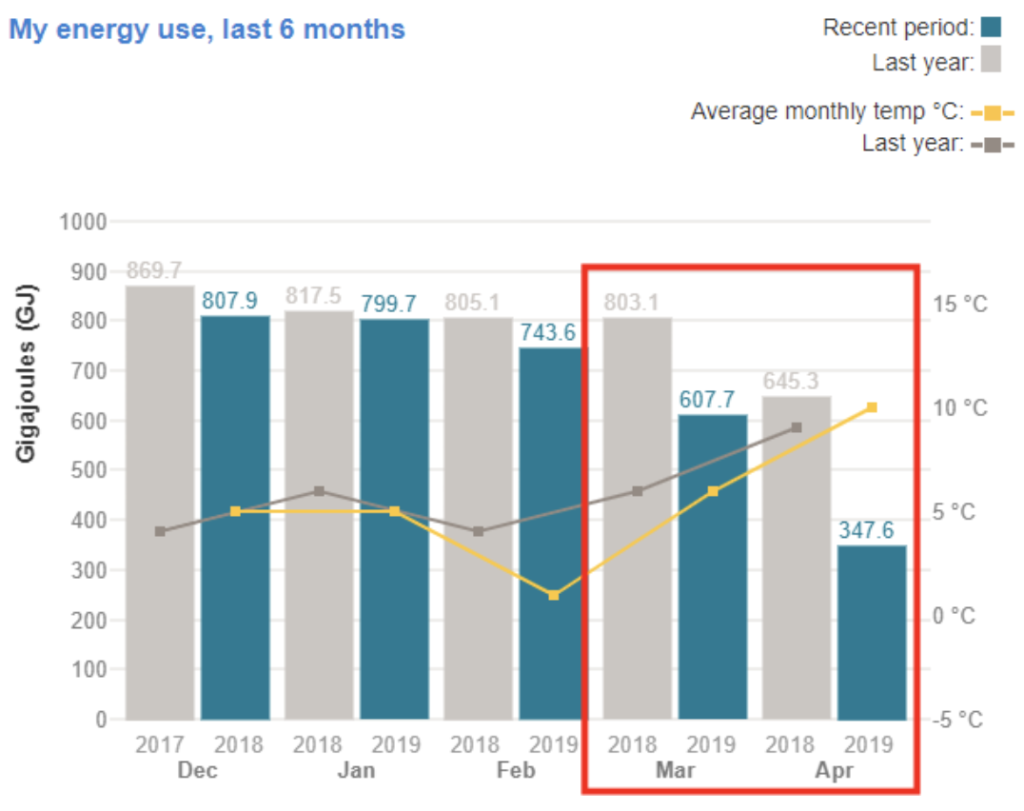

Polar worked with the City of Vancouver to replace the facility’s evaporative condenser with a fluid cooler and updated the compressors with new energy efficient models. These upgrades reduced the ammonia charge of the facility by 30%, increasing safety for operators and the public. As part of the project, Polar established a roadmap towards further ammonia reductions that when complete will reduce the plant charge by another 30%. Additionally, these upgrades laid the groundwork for energy recovery projects at Sunset Arena, resulting in reduced GHG emissions to help Vancouver meet its Climate Emergency Action Plan of 50% carbon reductions by 2030.