Energy Recovery &

Greenhouse Gas Reductions

The engineering team at Polar has worked with engineers in Europe to develop high temperature heat pumps which can directly integrate with your existing systems, such as your domestic hot water system. This innovation drastically reduces the capital investment required to build a heat recovery system, making it much easier than before to reuse your heat and reduce your carbon footprint.

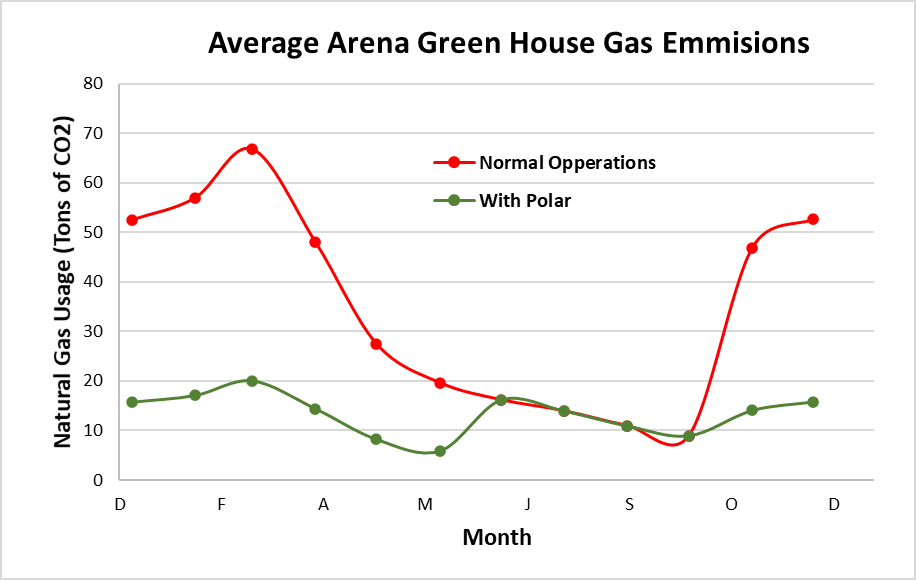

Working with our clients, the engineers at Polar have been able to design and implement energy recovery systems which reduced our client’s carbon footprint by over 85%.

THE FOLLOWING FACILITIES ARE GREAT APPLICATIONS FOR HEAT RECOVERY:

- Hockey arenas

- Industrial facilities

- Housing developments or city blocks using a district energy system

- Hospitals

- Curling clubs

- Large buildings with centralized heating and cooling plants.

Reduce fossil fuel emissions

Often the most cost-effective way to reduce your greenhouse gas emissions is to install one of Polar’s high temperature energy recovery systems. Our energy recovery systems have been designed to reduce the capital cost, when compared with a tradition energy recovery system, by more than 30%.

We have accomplished this by working with engineers in Europe to design a heat pump which can directly integrate with a boil loop. This drastically reduces the required piping, saves you a lot of money, and has the potential to reduce your GHG emissions by more than 90%.

Finally, ensure these systems have the shortest payback period possible, we help you apply for government grants to obtain up to 50% of the funding required to engineer and install a high temperature heat pump in your facility.

Reduce electrical consumption

The least expensive energy recovery option with the shortest payback period is often to reduce your electrical demands. To determine if this is the right direction for you, Polar will conduct an in depth engineering analysis of your refrigeration system to determine if you can benefit from reducing your electrical demand by operating your compressors with floating head, using VFDs to control your brine pump or condenser fan speed, or optimize your compressor operation. These power reduction measures can drastically reduce the power usage of a refrigeration plant by the following amounts and often have a payback period of less than 2 years.

To determine if CO2 is right for you the following questions are important to consider:

- Compressor floating head: Reduces refrigeration system power consumption between 15 and 30%.

- VFDs on pumps and fans: Reduces the brine pumps or condenser fans power consumption by more than 50%.

- Compressor optimization: This can increase the refrigeration system’s saturated suction and reduce the refrigeration systems global energy consumption by 4 to 8%.

In parallel with this in-depth engineering energy analysis, Polar will work with you to obtain grants which can cover 60% of the cost associated with installing one of these energy recovery measures.

Plant commissioning and energy audits

At Polar we understand that curling clubs are unique and require different design methodologies than other refrigeration systems. This is due to different curling club user groups, fiscal constraints, and operating conditions.

Using our experience designing and project managing curling clubs across North America, we work with our clients to ensure that the right refrigeration system is installed.