Energy Recovery &

Greenhouse Gas Reductions

Polar enjoys engineering air source or energy recovery heat pumps that drastically reduce the energy costs and carbon footprints of our clients’ large buildings.

Everybody is a winner when it comes to reducing fossil fuel emissions. Our clients save money on fuel costs and their carbon footprints are drastically reduced.

Electricity can be one of the highest operating costs of a larger building. Polar can work with you to reduce the annual electrical costs of your refrigeration system by 10% to 25%.

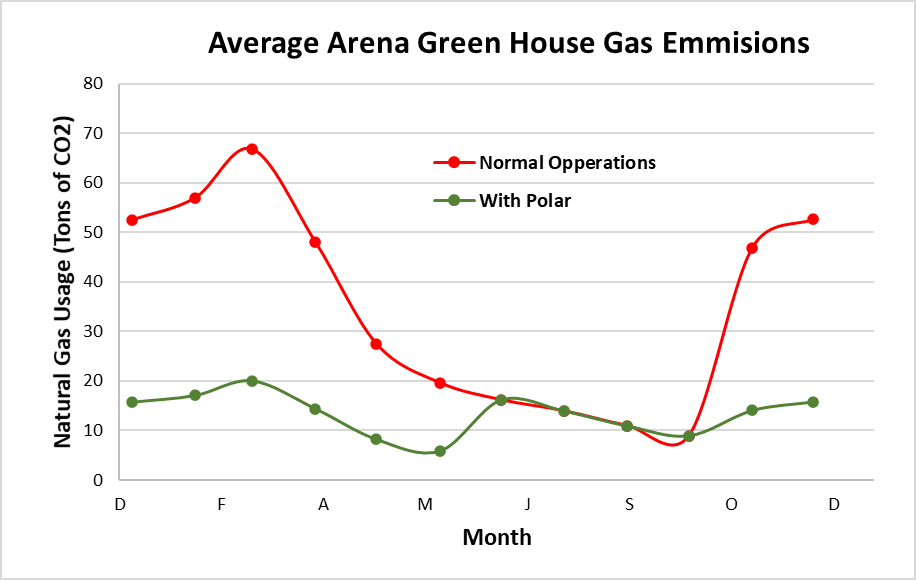

Working with our clients, the engineers at Polar have been able to design and implement energy recovery systems which reduced our client’s carbon footprint by over 85%.

For years, our clients have become world leaders in energy efficiency thanks to Polar’s cutting-edge energy recovery systems. Our high temperature heat pumps are able to integrate directly with your facility’s heating systems, allowing waste heat from your refrigeration system to meet the heating demands of your facility. Polar’s custom-designed, site specific heat pumps are 20-30% more efficient than competing off-the-shelf systems. This allows our clients to save more money, reducing the payback period of these systems by up to 5 years when compared to our competitors.

The engineering team at Polar has worked with engineers in Europe to develop high temperature heat pumps which can directly integrate with your existing systems, such as your domestic hot water system.

This innovation drastically reduces the capital investment required to build a heat recovery system, making it much easier than before to reuse your heat and reduce your carbon footprint.

Polar’s air source heat pumps extract energy from the outdoor air and use it to meet the heating demands of our clients' facilities. Because the outdoor air is an infinite source of energy, our air source heat pumps can be scaled to provide deep carbon cuts for your facility, reducing natural gas consumption and greenhouse gas emissions by up to 100%.

- Up to 100% GHG reductions

- Climate change-resistant system design

- Lower operating costs

- Improve system reliability

Hotels, Airports, Hospitals

At Polar Engineering, we understand that the operating costs of your facility have a significant impact on your bottom line.

Implementing an energy recovery system can dramatically reduce the natural gas and electricity consumption of your facility, leading to significant monetary savings for years to come.

Polar’s water source heat pumps can integrate directly with your facility’s central cooling loop, allowing the energy recovery system to provide simultaneous heating and cooling to your facility. This can provide significant reductions to your facility’s natural gas and electricity consumptions, while simultaneously increasing the capacity of your cooling system. Alternatively, our water source heat pumps can extract energy from water sources close to your facility, including lakes and the ocean, providing a free source of energy to reduce your facility’s consumption.

Reduce fossil fuel emissions

Often the most cost-effective way to reduce your greenhouse gas emissions is to install one of Polar’s high temperature energy recovery systems. Our energy recovery systems have been designed to reduce the capital cost, when compared with a tradition energy recovery system, by more than 30%.

We have accomplished this by working with engineers in Europe to design a heat pump which can directly integrate with a boiler loop. This drastically reduces the required piping, saves you a lot of money, and has the potential to reduce your GHG emissions by more than 90%.

Finally to ensure, ensure these systems have the shortest payback period possible, we help you apply for government grants to obtain up to 100% of the funding required to engineer and install a high temperature heat pump in your facility.

- Lower carbon footprint

- Lower operating costs

- Efficient and cutting-edge technology

- Designed specifically for your building

These power reduction measures can drastically reduce the power usage of a refrigeration plant and often have a payback period of less than 2 years.

- Reduced operating costs

- Lower demand charges

- Efficient operation

- Less maintenance

Reduce electrical consumption

- Compressor floating head: Reduces refrigeration system power consumption between 15 and 30%.

- VFDs on pumps and fans: Reduces the brine pumps or condenser fans power consumption by more than 50%.

- Compressor optimization: This can increase the refrigeration system’s saturated suction temperature and reduce the refrigeration systems global energy consumption by 4 to 8%.